end of arm tooling definition

1324 Goldsmith Plymouth MI 48170 Toll Free. End Of Arm Tooling Market.

Ultimate Guide To End Of Arm Tooling Eoat Dek

Sharples can provide components or finished End of Arm Tooling for your stacking and packing requirements.

. End effectors also known as End-of-Arm Tooling EOAT are devices that are attached to end of a robotic arm. ATI INDUSTRIAL AUTOMATION is the world-leading engineering-based developer of robotic accessories and robot arm tooling including Automatic Tool Changers Multi-Axis ForceTorque Sensing Systems Utility Couplers Material Removal Tools Robotic Collision Sensors Manual Tool Changers and Compliance Devices. Intelligent object detection is the key to complex automated applications.

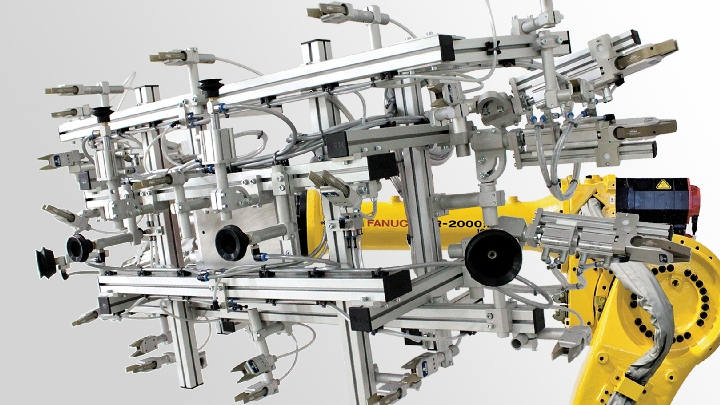

The end-of-arm tooling can directly manipulate the parts and components being produced or processed. For example the welding torch on a robotic welding system. End-of-Arm Tooling Kits are the simple solution to build a vacuum end-of-arm tool for an industrial robot to pick up virtually any shape or profile.

End-of-arm tooling experts will evaluate your project and determine the best solution for your application. The structure of an end effector and the nature of the programming and hardware that drives it depend on the task the robot will be. End-of-arm tools from Inovatech are custom designed and manufactured to be light-weight and reliable packing all of the features youd expect from a high-tech automation company.

This section provides company addresses contact details products and regional presence of companies who are purchasing or are likely to purchase End Of Arm Tooling over the coming years. Nylon PA-12 components have a high heat deflection temperature of 347 ºF 175 ºC. Showing results 1 to 10 of 28.

Inertia is calculated using the mass of the End of Arm Tooling. Milled lightweight end of arm robot plate fully assembled with. Robot End Of Arm Tooling EOAT components.

Lightweight and durable is the best combination for end of arm tooling. End of Arm Tooling. We have a staff of engineers with experience in all facets of tooling design ranging from insert applications to multi-robot systems that require no operator interface.

End-Of-Arm Tooling EOAT that adds value to the overall system. Unlimited design freedom for internal passages printed into the part for pressurized air water or vacuum. Robotic Automation Systems specializes in custom designed robustly engineered and constructed end of arm tooling EOAT grippers and end effectors for a wide range of robotic automation applications in horizontal and vertical plastic injection molding insert molding in-mold decorating IMD and in-mold labeling IML.

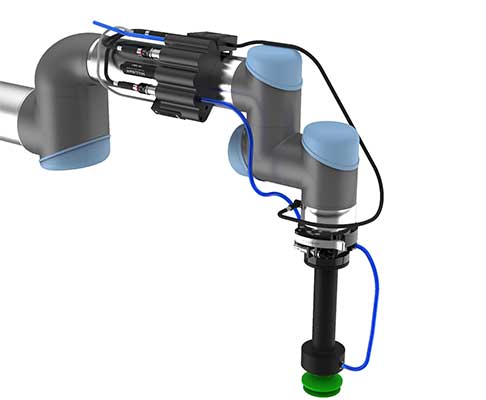

With extensive robotic automation experience for the manufacturing. Blue Water Controls has expertise in developing robust tooling for part handling. Baumer miniature sensors with an analog output or IO-Link provide precise position feedback of the gripper jaws.

Norgren carries standard End-of-Arm Tools EOAT a complete range of easy to assemble modular end-of-arm tooling components and fully configured solutions. DESTACO has been providing end effector tooling in nearly every global market segment for over 30 years offering full turnkey design manufacturing. In robotics an end effector is a device or tool thats connected to the end of a robot arm where the hand would be.

Although many types of tooling appear similar even the subtlest changes can have a profound impact on an entire automation systems efficiency. Our robot end-effector products are found in. End-of-Arm Tooling Grippers automatic tool changers.

Piab provides an extensive offering for all types of palletizing and de-palletizing operations no matter if you are looking for ergonomic handling equipment components and sub-systems to build your own End of Arm Tool or ready- to- use palletizing End of Arm Tool for industrial robots or collaborative robots. We can integrate our End of Arm Tooling EOAT onto robots from all the major manufacturers and can provide 3D design files for all. The end effector is the part of the robot that interacts with the environment.

Custom Designed End of Arm Tooling. End of Arm Tooling EOAT refers to any device that is attached to the end of the robots arm that allows the robot to interact with parts in the environment and assists in the completion of a task. The payload is easier to measure and easier to calculate.

In this way the gripper itself becomes a measuring. They are designed and used to act as robot wrists that interact with the environment. From servo grippers and hybrid tooling to advanced tool changers and control modules todays EOAT is not only easier to implement and easier to use its down right smart.

3D Printed end of arm tooling components are made of Nylon and can be up to 70 lighter than Aluminum components. It refers to the equipment that interacts with parts and components typically at the end of a robotic arm. UNITED STATES ASS End of Arm Tooling Inc.

8020 T-Slotted Extrusion One of the many benefits of T-slotted profile and parts is their versatility creating everything from machine guarding to robot arms and workstations. Inertia is a property of matter where the object resists changes in velocity speed andor direction. End of arm tooling EOAT is a crucial aspect of robotic technology.

Parallel grippers Automatic tool changers Parallel grippers Automatic tool changers Parallel grippers. Sensor solutions for robotics. End-Use Landscape The end-use landscape entails a list of current and prospective consumers prevailing across the regions.

Payload includes the weight of the End of Arm Tooling EOAT and the weight of the product being picked. Through the use of our in-house CNC and 3D printing capabilities every tool we build consists of light-weight. The EOAT gives a robot a specific functionality and can be changed to fit different applications or even be.

Our end-of-arm-tooling integrates vacuum generators suction cups and fittings together for a modular solution with minimal set and simplified connections. This paper describes about recent trends in robotic gripper and its applications. We provide clean and simple designs taking into consideration ease of adjustment and component availability.

The sensitivity of grippers and gripper arms is becoming increasingly important especially when it comes to flexible production and batch size 1. End of arm tooling may vary greatly between applications depending on the parts being handled and the actions the robot is required to. End-of-arm tooling - sensor solutions for robotics.

8 Types Of End Of Arm Tooling Devices Grippers Keller Technology

Eoat Meaning Types Magnetic Gripper Manufacturer Hvr Mag

4 Robot End Of Arm Tooling Inlearc

4 Robot End Of Arm Tooling Inlearc

End Of Arm Tooling Robot End Effectors Millibar Robotics

Eoat Meaning Types Magnetic Gripper Manufacturer Hvr Mag

Robotworx Selecting End Of Arm Tooling